Car unloading can be divided into two types: manpower and machinery:

Loading and unloading machinery for containers and pallets. Container handling Bridges, gantry or tire cranes, straddle forklifts and large forklifts, and container trucks with their own loaders. Some countries often use what are called "detachable unloading methods" to load and unload containers. During unloading, the supporting container, the car moves forward and the chassis is removed from the case. Instead, when loaded, the chassis of the car falls back to the bottom of the box, the support feet close, and the box lands on the chassis and tightens. The main machinery for pallet loading and unloading is forklift truck and pallet loader. Forklifts are available in a variety of types, equipped with accessories and widely used. They are one of the key equipment in stations and warehouses. The pallet loader is a simplified small forklift suitable for loading, unloading and palleting of warehouses and compartments.

(2) Vehicle-mounted loading and unloading equipment. There are two main types of elevatable rear railings (also known as rear railing lifts) and cranes. The former allows the tailgate to fall horizontally to the ground, or it can be raised by electro-mechanical or electro-hydraulic drives to the same height as the floor of the carriage. It ACTS as a car fence when driving and as a lift when loading and unloading. This equipment is used in conjunction with a trolley, stacker or pallet with roller, and has achieved good results. Vehicle-mounted cranes are mostly installed behind the cab. For example, a truck trailer is located between a truck and a trailer. The crane can be equipped with various accessories according to different loading and unloading cargo, such as grab, fork, scrap grab, brick clamp, etc., so as to expand its scope of use.

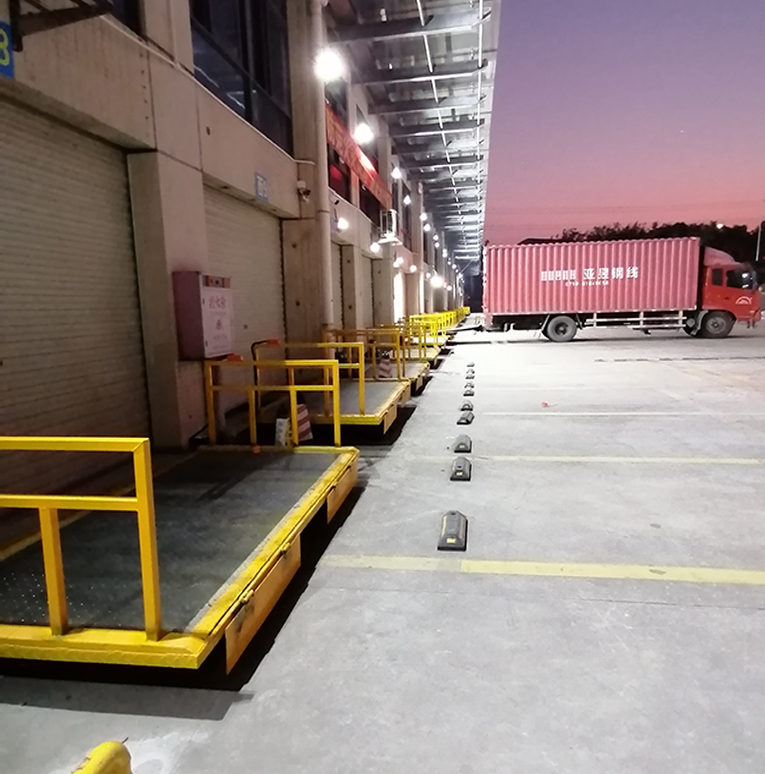

(3) All kinds of leveling devices, conducive to loading and unloading operations. There are two levelling devices to keep the warehouse platform and cage floor level. One is the lifting platform, fixed and moving. Fixed on the front of the platform, with large lifting capacity, some can lift the vehicle; The elevations range widely, from a few centimeters to a few meters. The overall size of the mobile lifting platform is relatively small and the lifting capacity is not big. Typically, manual movement is used. The second is the connection between the vehicle and the platform. This is a gangway or other device used as a bridge. It can also be classified as fixed or mobile. Removable springboards usually use simple rings or hinged springboards that can be folded. Fixed types are mostly fixed at the front end of the warehouse platform. Some are suspended vertically when not in use and supported only when in use; Other locking mechanisms embedded in the platform, which are the same as the platform when not in use, automatically support the vehicle as it approaches, and adjust the height by means of counterweights or springs or hydraulic devices to accommodate the height of the vehicle.

Professional to provide security

for modern logistics

A new company that efficiently handles

and unloads equipment

Please do not hesitate to contact us

0769-81251088

Add friend consultation